ROOP TELSONIC ULTRASONIX LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ROOP TELSONIC ULTRASONIX LTD.

Ultrasonic Liquid Processing

We Process Faster

Within the ultrasonic liquid processing domain, a wide range of chemical and physical processes can be influenced by our state of the art ultrasonic equipment.

Numerous chemical and physical processes can be performed such as the disruption of cells, preparation of emulsions and dispersions, homogenizing of liquids, acceleration of various chemical reactions, atomization, degassing of liquids and the extraction of several substances from organic sources. Furthermore, the equipment is ideally suited for development activities in the area of sono-chemistry research.

Important processes can be optimized with ultrasonic's. Especially for chemical processes, the use of greater vibrations ensures augmented efficiency, resulting in faster workflows, improved productivity as well as reduced operational costs.

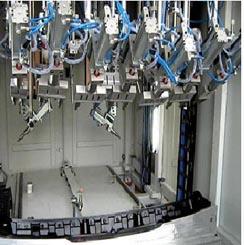

Powder Screening Or Sieving

We have TRANSFORMED sieving

With our high tech ultrasonic sieving equipment we have transformed conventional sieving procedures. Not only can the screening process be accelerated radically (Up to 30 times) also the mesh quality and its lifetime can be increased. Also you improve your throughput and the quality of your products.

In addition to the conventional method, " SONOSCREEN" ultrasonic supported sieving technology evenly transmits as oscillating motion, in the micron range, onto the screen surface reducing the friction between the sieve mesh and bulk material. This Enhances the throughput and quality of your present vibratory screener, sieve or sifter.

Our revolutionary ultrasonic powder sieving system can be applied to your existing sieve, screener, or sifter to eliminate blockage or screening of wire mesh while sieving powder products such as powdered metals, ceramics, powder coatings, pharmaceuticals, or food additives.

Depending upon the particle structure this reduction can result in a significant increase in throughput volume. Screen blinding and clogging are also reduced due to the cleaning effect the oscillating motion has on the sieve mesh. A consistent efficient production process is guaranteed while simultaneously reducing the related maintenance costs to a minimum." SONOSCREEN" can be applied to both wet and dry sieving applications.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.